Rubber lagging for pulleys is essential to improve conveyor belt performance. The use of rubber lagging improve tracking, reduces belt slippage and prolong life of belt, bearing and other accessories.

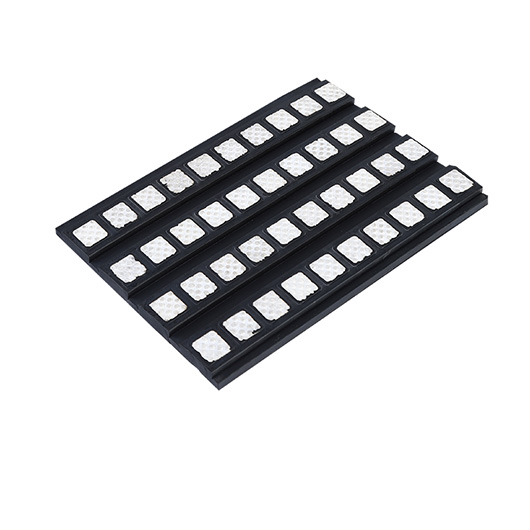

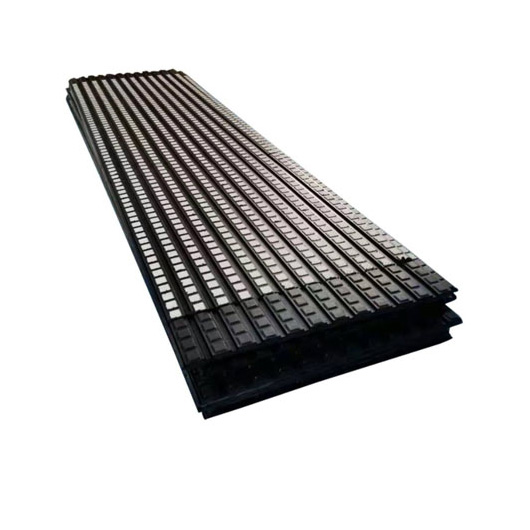

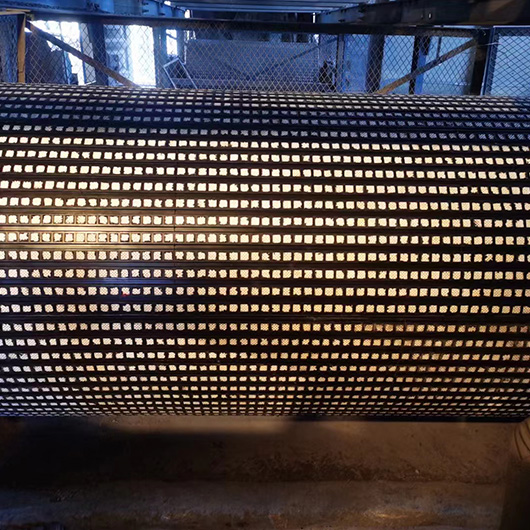

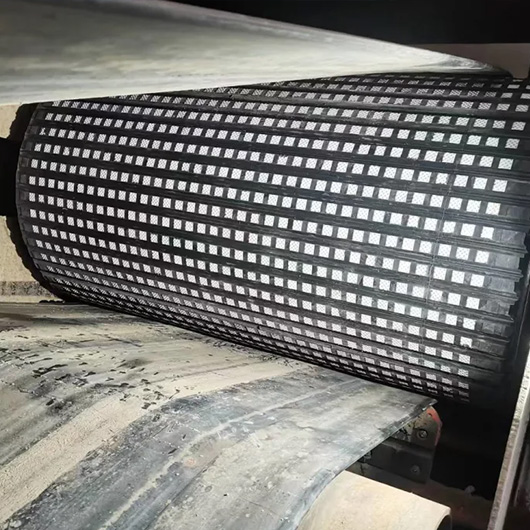

Ceramic pulley lagging is specially suited for pulleys where slippage and excessive wear and tear problems which make normal rubber lagging ineffective. The ceramic lagging widely used on the drive pulleys, can also be used on snub, bend and tail pulleys, special suited belt under wet, muddy or other extreme working conditions.

Drive pulley

Tail pulley

High strength conveyor system

Wet or muddy conditions

High wear conveyor system

Super abrasion resistant

Prevent belt from slippage

Increase traction & friction value

Prolong life of the belt

|

Order No. |

Thickness. mm |

Width. mm |

Length. mm |

|

100012 |

12 |

500 |

10000 |

|

100015 |

15 |

500 |

10000 |

|

100020 |

20 |

500 |

10000 |

* Both CN layer and Non CN layer is available

* Flame retardant is available

* The length of ceramic lagging rubber can be customized

* Ceramic tile (Al2O3): 95%